The smart Trick of Laser Cutting Equipment That Nobody is Discussing

Wiki Article

With regards to modern production, the precision and effectiveness of laser cutting engineering are truly activity-changing. Laser cutting equipment have revolutionized industries by supplying a approach to chopping materials with unparalleled accuracy. For those who’ve ever marveled for the intricate layouts on metallic or questioned how sophisticated styles are manufactured so seamlessly, it’s normally the function of the industrial laser cutting equipment.

Enable’s get started with the fundamentals: a laser cutter is actually a Resource that works by using a laser beam to cut products. This beam is unbelievably concentrated and generates substantial temperatures to soften or vaporize the fabric, producing precise cuts. Not like conventional techniques, which could use mechanical blades, a laser cutter offers a standard of accuracy that is almost unmatched. Envision wanting to carve a delicate pattern that has a hammer—Evidently, a laser cutter is a lot extra refined!

Industrial laser cutting can take this technological innovation to the next degree, delivering methods for giant-scale functions. These devices are built to manage significant supplies and higher manufacturing volumes, ensuring that even one of the most demanding initiatives are accomplished with substantial efficiency. Imagine it given that the distinction between using a precision knife for sensitive paper crafts and a strong observed for reducing through thick Wooden.

Some Ideas on Laser Cutting Systems You Should Know

On the planet of CNC laser cutting, the “CNC” means Personal computer Numerical Regulate. This technological innovation allows for automatic and really precise cuts by pursuing digital models. In case you’ve at any time utilised a pc to draw and afterwards noticed that drawing arrive at daily life, CNC laser cutting performs in an identical way, translating electronic models into Actual physical cuts. It’s like getting a Digital designer with the precision of the laser.

On the planet of CNC laser cutting, the “CNC” means Personal computer Numerical Regulate. This technological innovation allows for automatic and really precise cuts by pursuing digital models. In case you’ve at any time utilised a pc to draw and afterwards noticed that drawing arrive at daily life, CNC laser cutting performs in an identical way, translating electronic models into Actual physical cuts. It’s like getting a Digital designer with the precision of the laser.Not known Factual Statements About Laser Cutting Services

Precision laser reducing isn't pretty much building cuts; it’s about generating them right each time. The laser is usually adjusted to achieve diverse depths and widths, making sure that each Slice is strictly in which it should be. This is certainly critical for programs where even a slight deviation could lead to sizeable issues. Visualize it like a surgeon’s scalpel, exactly where precision is not merely critical but absolutely important.

Precision laser reducing isn't pretty much building cuts; it’s about generating them right each time. The laser is usually adjusted to achieve diverse depths and widths, making sure that each Slice is strictly in which it should be. This is certainly critical for programs where even a slight deviation could lead to sizeable issues. Visualize it like a surgeon’s scalpel, exactly where precision is not merely critical but absolutely important.Laser cutting products is available in different sorts, Each individual customized to particular requirements. Irrespective of whether You will need a little desktop model for pastime projects or a huge industrial machine for factory use, there’s a laser reducing Resolution around for yourself. These machines change in electricity, velocity, and abilities, so it’s vital that you select the appropriate a person for the individual application.

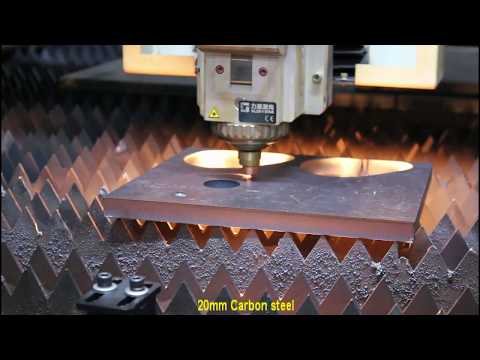

Sheet metallic laser cutters absolutely are a Specific class of laser chopping machines made specifically for slicing metallic sheets. These are extensively Utilized in industries ranging from automotive to aerospace because of their power to manage metallic with precision and speed. Photograph a sheet of steel similar to a blank canvas, as well as laser cutter as the artist who produces elaborate and delightful designs with amazing precision.

Laser cutting products and services are another significant element of this technological innovation. Not Every person needs to take a position in their very own laser chopping equipment, particularly when they only have to have occasional cuts or deficiency the Area for these devices. Numerous businesses offer you laser reducing expert services in which you can send your models and also have them Slash with large precision. It’s like outsourcing your artwork to a talented Qualified.

Laser chopping devices combine learn more several parts to provide the specified success. Through the laser source to the slicing bed, along with the Manage software, each individual A part of the system functions alongside one another to ensure a flawless Procedure. It’s a bit similar to a symphony orchestra, wherever Every single musician has a particular part, and only by Doing the job collectively do they make a harmonious overall performance.

When it comes to laser cutting technology, the evolution continues to be immediate and amazing. Originally made use of primarily for slicing metals, these devices now tackle a wide range of materials together with plastics, wood, and even fabrics. This flexibility will make laser reducing technology a valuable tool in numerous industries. Consider using a Swiss Military knife which can manage nearly any content—This can be what modern day laser chopping technologies presents.

The accuracy of laser reducing devices is really exceptional. They are able to cut materials to in just microns from the intended style, making sure that even the most intricate information are preserved. This volume of precision is particularly precious in industries where specific measurements are critical. Consider it as the distinction between a personalized match and off-the-rack clothing—the in shape is just ideal whenever.

Industrial Laser Cutting Can Be Fun For Everyone

Yet another benefit of laser cutting technological innovation is its efficiency. Compared with classic cutting solutions that might call for numerous measures or instruments, laser slicing frequently completes the endeavor in a single go. This not just hastens output but also lowers substance waste. It’s like having a high-velocity prepare that gets you towards your desired destination quickly and successfully with no needless stops.During the context of industrial apps, the robustness of laser reducing machines is important. These machines are created to endure the requires of constant Procedure, frequently operating 24/seven in high-quantity settings. Their sturdiness ensures constant effectiveness and reliability, which happens to be essential for protecting production schedules. It’s like having a significant-duty truck that reliably provides merchandise day after day.

Among the list of outstanding aspects of laser slicing is its ability to develop clean and specific edges. This cuts down the necessity for publish-processing, like sanding or ending, which can be time-consuming and expensive. The end result is usually a sleek, concluded solution That always calls for minimum supplemental get the job done. Envision finishing a craft challenge without having glue spills or tough edges—it’s that clean!